Holistic and automated material flow with omlox

Due to increasing and volatile demand in eCommerce, shaken supply-chains and labor shortages, there is a lot of emphasis on automation in intralogistics these days. Logistics companies are deploying automated guided vehicles, robots and invest in modernization of their IT landscape. Systems are becoming increasingly complex which poses the need for interoperable and open standards. In this context, the open locating standard omlox hosted by PI (PROFIBUS & PROFINET International) can be a real gamechanger, as it can provide full transparency on every movement in logistic sites. It specifies a locating-middleware to aggregate location data in a technology-independent manner (omlox hub) and an interoperable Ultrawide-Band System (omlox core zone) to provide real-time tracking in challenging environments.

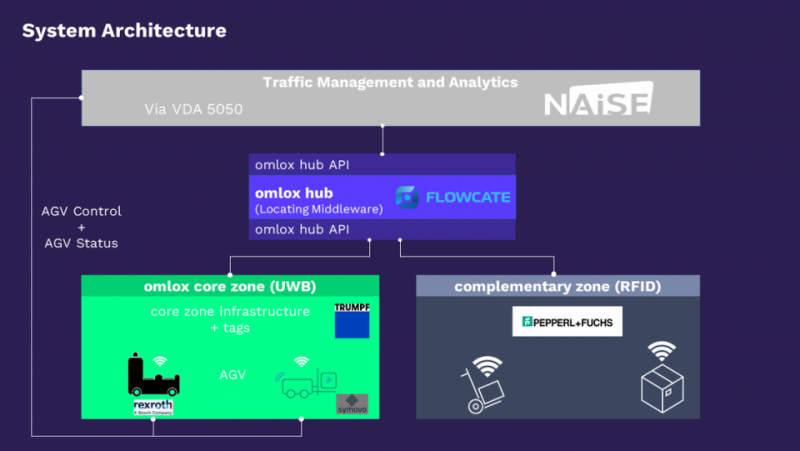

A group of omlox partners has joined forces, to demonstrate by means of a showcase a holistic automated material flow, following the omlox architecture and the specified APIs. In this setup, NAiSE is providing its fleet management solution. This traffic management software uses the VDA 5050 standard to orchestrate AGVs and is adopting the omlox APIs to receive information about locations of other objects like persons, palettes, or small load carriers. Those objects are tracked within an omlox core zone, by TRUMPF Tracking Technologies and by using RFID from Pepperl & Fuchs as omlox complementary zone. The location data is aggregated within an omlox hub, provided by Flowcate. Furthermore, the omlox hub is providing spatial events like fencing and collisions, to foster a frictionless material flow and safety on site.

As all partners follow the standardized omlox API and architecture, the overall system becomes “plug and play” and further locating technologies and use-cases can easily be added. It provides the framework for a future proof setup on a logistic site, while incorporates existing technologies. Due to the fact, that an omlox application provides geo-references location data, the complete system can be embedded into general supply chain management solutions, to enable a seamless tracking of material across sites.

Application Scenarios/ Use of Location data:

1. Getting different position data in one system (Manual Guided Vehicles & Persons via UWB, AGVs/AMRs via NAiSE APP, Load carriers via RFID)

2. Triggering Geofence Events with position data

a. Geofence Event for Traffic Light

b. Narrow Zone Event

c. Order Triggering via RFID Position data

3. Traffic Management to control AGVs/AMRs regarding position data

4. Analytics with position data in NAiSE APP

Contact us for more information.