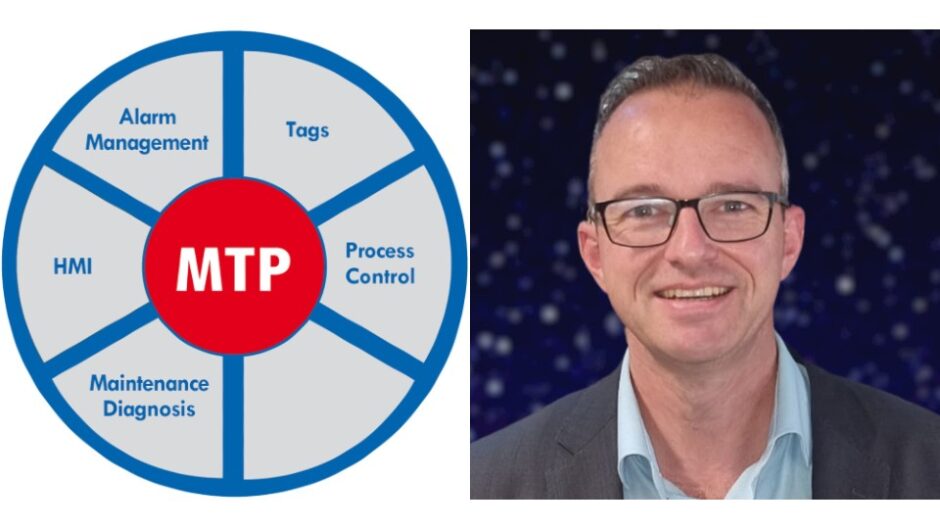

Flexibility, interoperability or efficiency? Get it all with MTP!

Flexible production plants, interoperability, and efficiency do not need to be contradictory. With the Module Type Package (MTP) technology, all these goals can be achieved at the same time. Sounds like a dream? In summer 2023, NAMUR, ZVEI, and PI joined their forces to make this dream reality. Since then, nearly 50 experts from plant owners, system integrators, machine builders, and automation suppliers meet several times a week in joint working groups to develop a consistent set of specifications and interoperability tests to make this reality.

Orchestration Instead of Engineering

MTP plays an important role in the digitalization of industrial plants to improve efficiency, sustainability, and resilience. MTP will significantly affect key performance indicators for plants in the future. Initial results show that the average time to market can be halved, engineering effort can be reduced by 70 percent, and flexibility can be increased by 80 percent. This is achieved by orchestrating pretested Process Equipment Assemblies (PEA):

- digitally, within the engineering subsystem of the Process Orchestration Layer (POL) based on the MTP file itself, which contains a semantic description of the PEA, and

- physically, which is controlled by the runtime system of the POL.

Orchestration in the digital world comprises the import of the MTP file, performing potential adaptations within the HMI screens imported from the MTP, and configuring the topology and network properties. Since the address information of all tags, the objects on the HMI screens, the interfaces for all parameters, and services are part of the MTP, the effort for the orchestration of the plant is reduced massively compared to a classical plant engineering approach.

In the real plant, orchestration boils down to monitoring and control of the technical process, for which the POL uses the services and visualizes the runtime data of the PEAs. Furthermore, time and effort for commissioning can be cut down if the PEAs used within the plant are pretested. This even may account for validation efforts in regulated industries.

Tackling the Interoperability Challenge

The PEAs within one plant are engineered and manufactured by various OEMs, each using automation components from their preferred automation suppliers. It is the goal of the MTP technology to ensure that all PEAs with their different automation systems can be orchestrated from one POL.

The first building block to achieve this goal is the release of a consistent set of MTP specifications currently being developed in the Joint Working Groups of NAMUR, ZVEI, and PI. This MTP Specification is planned to be released in fall 2024 as an industry standard from NAMUR and PI. It will replace the VDI/VDE/NAMUR 2658.

The second building block are interoperability tests, which can be executed by independent test labs. These tests as well as test procedures are currently developed in the Joint Working Group MTP Quality based on PIs’ profound experience in certification.

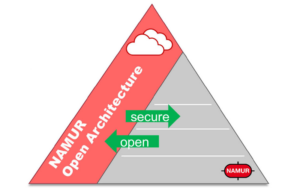

NOA Completes the Story

Orchestration of pretested PEAs means encapsulation of engineering information. Encapsulations reduces complexity. However, encapsulation limits transparency, because only the information, which is accessible via the MTP interface, can be seen from the POL. Exactly at this point, NAMUR Open Architecture (NOA) completes the story. NOA specifies information models for monitoring and optimization on the sensor and, in the future, actuator level. MTP and NOA can be perfectly combined. MTP enables the efficient orchestration of pretested PEAs to control the technical process. NOA gives access to the data on sensor/actuator level from within each PEA to implement monitoring and optimization use-cases.

Internationalization

With the setup of the joint working groups within PI with its strong worldwide network, a first step towards the internationalization of the MTP technology has been made. Furthermore, the work in IEC has been restarted. The first steps to publish the MTP Specification as IEC 63280 have been done!

The functionality, strengths and user benefits of MTP have been presented at the PI booth at SPS in Nuremberg and at ITAP in Singapore using a live demo with products and solutions from more than 10 innovative manufacturers. This year, I am glad to invite you to Hannover Messe and Achema. Visit the PI booth and get an impression on how to improve flexibility, interoperability and efficiency or simply how to get it all with MTP!