A new profile for robot systems

One of the core tasks of PROFIBUS & PROFINET International (PI) is the cross-manufacturer standardization of data interfaces for enabling easy, interoperable communication in automation systems. In addition to the tried-and-tested PROFIsafe, PROFIdrive, PROFIenergy and PA profiles, PI is now getting started with a profile for robot systems – an expansion of its technology portfolio for better operating new applications. To develop this new profile, PI created a new “Profile for Robot Systems” working group.

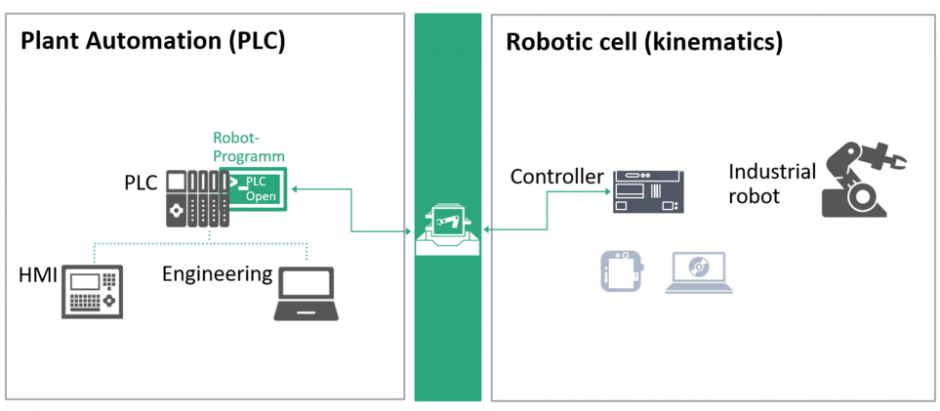

In modern production lines, stationary robots are increasingly being integrated as a complete system so as to increase the degree of automation and reduce costs. As the production line is typically controlled by a PLC and the user carries out programming of the production line application using the programming system of the PLC, it’s necessary to control and program complete robot systems from different manufacturers which are integrated into the production line in a uniform way using the PLC programming system.

Against this backdrop, a uniform data interface between the PLC and robot controllers needs to be defined in order to make robot programming uniform – and therefore more efficient – for PLC programmers and PLC suppliers. This data interface has to make it possible to write robot programs fully within the PLC. As a result, the PLC manufacturer then only needs a single robot library based on this data interface and the robot manufacturer only has to implement a single interpreter for their robot controller. The robot functions are to be called over the data interface, and the required robot status information reported back to the PLC.

The primary target group of this interface concept are PLC and robot programmers who are implementing a machine or production line (OEM), including robots, but machine operators and system owners (end customers) benefit from this as well.

For implementation, all previously known robot functions are to be defined in this data interface in a manufacturer-neutral way, where the focus lies on application handling. The preliminary work of the “Standard Robot Command Interface” project group is to be used as a basis here.

Please do contact us for more information.